Introduction

Table of Contents

In reinforced concrete construction, lap splicing is an essential practice. Since steel bars used in RCC are manufactured in standard lengths (typically 12 meters), it becomes necessary to join two bars to maintain continuity of reinforcement. This is where the lap length formula plays a critical role.

Proper lap length ensures that stress is safely transferred from one bar to another through the surrounding concrete. An incorrect lap length can lead to structural failure. This comprehensive guide explains the lap length formula as per IS 456, its application in columns, beams, slabs, and footings, and how to calculate lap length for different reinforcement scenarios.

What is Lap Length?

Lap length is the length of overlapping between two reinforcement bars that ensures the transfer of load from one bar to another. The overlap is created so that the bars act as a single continuous unit.

There are different lap lengths depending on:

-

Type of member (beam, column, slab, footing),

-

Bar diameter (d),

-

Grade of concrete,

-

Grade of steel,

-

Whether the bar is in tension or compression.

Lap Length Formula as Per IS 456

According to the IS 456:2000 code of practice, the lap length formula varies based on the type of stress (tension or compression) and the position of reinforcement.

1. Tension Lap Length (Flexural or Direct)

For bars in tension, lap length should not be less than:

-

30 times the bar diameter (30d)

OR -

The development length (Ld), whichever is greater.

2. Compression Lap Length

For bars in compression, lap length should not be less than:

-

24 times the bar diameter (24d)

OR -

The development length (Ld), whichever is greater.

This is the general lap length formula is 456 guideline applicable to all RCC structures.

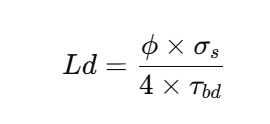

Development Length (Ld)

Before diving into specific applications, it’s important to understand development length. This is the minimum length required to develop the full strength of the reinforcement bar through bond with the surrounding concrete.

Formula:

Where:

-

ϕ\phi = Diameter of the bar

-

σs\sigma_s = Stress in the bar (usually 0.87 × yield strength)

-

τbd\tau_{bd} = Design bond stress

Lap length is often derived as a multiple of bar diameter (d) based on the Ld calculation.

Lap Length in Different RCC Members

Let’s explore the lap length requirement member-wise.

Column Lap Length Formula

Columns primarily carry compressive forces. Therefore, column lap length formula is based on compression lap rules.

Lap Length Formula for Column:

-

As per IS 456:

Lap Length = Ld (Compression) but not less than 24d

General Practice:

-

Column lap length = 40d to 45d

Additional Guidelines:

-

Laps should be staggered and placed at different levels.

-

Provide extra ties (stirrups) around the lapping zone for confinement.

-

Avoid lapping in heavily stressed regions.

Beam Lap Length Formula

Beams generally carry flexural (bending) stress, resulting in tension in the bottom steel and compression in the top.

Lap Length Formula for Beam:

-

Bottom bars (tension):

Lap Length = Ld or 30d (whichever is greater) -

Top bars (compression):

Lap Length = Ld or 24d

Beam Lap Zones:

-

Avoid lapping near points of maximum moment.

-

Prefer lap splices near supports where bending moments are low.

Beam Lap Length Formula in Practice:

-

Tension zone: 50d to 60d

-

Compression zone: 24d to 30d

Slab Lap Length Formula

Slabs generally have lesser loads than beams and columns, but still require proper bar continuity.

Lap Length Formula for Slab:

-

Mostly in tension (bottom mesh)

-

Use:

Lap Length = Ld or 30d

(Typically 50d is used in practice)

Additional Guidelines:

-

Ensure lapping is done away from mid-span areas.

-

Laps should be provided staggered in alternate bars.

-

Minimum clear lap spacing should be 1.3 × lap length.

Footing Lap Length Formula

Footings are responsible for transferring building loads to the ground. The top bars are usually in tension while bottom bars are in compression.

Lap Length Formula for Footing:

-

Tension bars (top):

Lap Length = Ld or 30d -

Compression bars (bottom):

Lap Length = Ld or 24d

Reinforcement Detailing:

-

Ensure bars are properly anchored into the column reinforcement.

-

Provide extra ties or stirrups in the lap zone for additional support.

Steel Lap Length Formula

The steel lap length formula is based on the type of stress and IS 456 guidelines.

Summary:

| Stress Type | Formula | Minimum Lap Length |

|---|---|---|

| Tension | Max (30d, Ld) | 30 × bar diameter |

| Compression | Max (24d, Ld) | 24 × bar diameter |

Steel lap length formula also applies to deformed bars, TMT, or high-yield strength bars.

Rebar Lap Length Formula

The rebar lap length formula is applicable for splicing steel reinforcement bars (rebars). It’s the same as the steel lap length formula, but with practical detailing considerations:

-

Rebar laps must not occur in highly stressed regions.

-

For bars of unequal diameters, use smaller diameter (d) in calculation.

-

For larger bars (≥36 mm), welding is preferred over lap splicing.

-

The lap zone must have proper confinement through ties or stirrups.

Reinforcement Lap Length Formula

To summarize, the reinforcement lap length formula is:

-

In tension:

Lap length = Max(30d, Ld) -

In compression:

Lap length = Max(24d, Ld)

Also:

-

Minimum lap length = 15d or 200 mm, whichever is greater.

-

For bundled bars, lap length should be increased by 10%.

This reinforcement lap length formula is applicable for all RCC members including slabs, columns, beams, and footings.

Lap Length Formula Chart (Quick Reference)

| RCC Member | Tension Zone | Compression Zone | Typical Lap Length |

|---|---|---|---|

| Column | 30d | 24d | 45d |

| Beam | 30d | 24d | 60d (tension), 30d (compression) |

| Slab | 30d | N/A | 50d |

| Footing | 30d (top) | 24d (bottom) | 50d (top), 40d (bottom) |

| General | 30d | 24d | As per IS 456 |

Important Notes on Lap Length Design

-

Bar Diameter Impact: Always calculate lap length using the smaller diameter when different sizes are joined.

-

Lapping Location:

-

Avoid at the mid-span of beams and slabs.

-

Avoid in the center region of columns.

-

Place laps in low-stress zones.

-

-

Staggering of Laps: Never provide laps for all bars in the same location. Stagger them to distribute the stress and maintain integrity.

-

Confinement Reinforcement: Extra stirrups should be provided around lap zones in columns and beams to improve bond and stress transfer.

-

Bar Type: Use deformed bars or TMT bars for better bond strength and shorter lap lengths.

-

Construction Practices: Ensure full contact between overlapped bars with proper binding using tie wire.

Frequently Asked Questions (FAQs)

Q1. What is the lap length formula for 16 mm bar in beam?

Answer:

-

In tension:

Lap length = 60 × 16 = 960 mm

Q2. Is lap length same as development length?

Answer:

No. Development length is the length required to develop the full stress in a bar. Lap length is used to splice two bars and is based on development length and bar diameter.

Q3. Can lap length be reduced?

Answer:

Only under specific conditions such as:

-

Use of welded joints instead of laps

-

Increased concrete cover and confinement

-

Use of mechanical splices

Q4. What is the minimum lap length?

Answer:

As per IS 456:

-

Minimum lap length = 30d in tension, 24d in compression, but not less than 200 mm.

Conclusion

The lap length formula is a critical aspect of reinforcement detailing in RCC structures. Based on IS 456:2000, it ensures structural continuity, stress transfer, and safety. Whether it’s a beam, column, slab, or footing, applying the right lap length for steel bars (rebar) according to their diameter and stress condition is essential.

Following the guidelines of lap length formula for column, beam lap length formula, slab, and footing, as discussed above, ensures that your structure meets safety codes and performs well under load.